Mining

|

|

|

Miners washing the hill side down into the sluice box

Miners washing the hill side down into the sluice box

Mine

an excavation in the earth for extracting coal or other minerals.

Mining

the process or industry of obtaining coal or other minerals from a mine.

Mining is the excavation of a claim or private land with means of extracting valuable minerals and ores. there are different techniques used. Surface mining and underground mining are some different techniques used in mining. the different equipment used goes from big machines down to small panning equipment. We will be exploring the smaller sized equipment in the Mining Equipment section of this web site.

an excavation in the earth for extracting coal or other minerals.

Mining

the process or industry of obtaining coal or other minerals from a mine.

Mining is the excavation of a claim or private land with means of extracting valuable minerals and ores. there are different techniques used. Surface mining and underground mining are some different techniques used in mining. the different equipment used goes from big machines down to small panning equipment. We will be exploring the smaller sized equipment in the Mining Equipment section of this web site.

Placer Mining

Placer mining is frequently used for precious metal deposits, particularly gold which is often found in alluvill deposits—deposits of sand and gravel in modern or ancient stream bed, or occasionally glacial deposits. The metal having been moved by stream flow from an original source such as a vein, are typically only a minuscule portion of the total deposit. Since gems and heavy metals like gold are considerably more dense than sand, they tend to accumulate at the base of placer deposits.

The containing material may be too loose to safely mine by tunneling, though it is possible where the ground is frozen. Where water under pressure is available, it may be used to mine, move, and separate the precious material from the deposit, a method known as hydraulic mining slucing or hydraulicking.

Placer mining is frequently used for precious metal deposits, particularly gold which is often found in alluvill deposits—deposits of sand and gravel in modern or ancient stream bed, or occasionally glacial deposits. The metal having been moved by stream flow from an original source such as a vein, are typically only a minuscule portion of the total deposit. Since gems and heavy metals like gold are considerably more dense than sand, they tend to accumulate at the base of placer deposits.

The containing material may be too loose to safely mine by tunneling, though it is possible where the ground is frozen. Where water under pressure is available, it may be used to mine, move, and separate the precious material from the deposit, a method known as hydraulic mining slucing or hydraulicking.

Lode Mining or Hard rock

This mining method requires digging into solid rock to find minerals in their raw ore form. The simplest form of lode mining is utilizing picks and shovels, but rock drills and dynamite are most often used. Shafts might go straight down into the ground or advance horizontally into a mountain faces. Shafts and tunnels are often supported with large timbers to prevent cave-ins. Deep shafts are generally accompanied by a head frame to support a hoists so material could be brought to the surface. These types of mines almost always eventually flooded as they get closer to the water table. Large pumps are used to remove the water.

This method of gold mining is responsible for recovering most of the worlds gold supply.

The startup costs for this type of mining can be extremely high. The work of drilling and basting into solid rock can be extremely dangerous and it's backbreaking labor. That is why most recreational miners concentrate on the placer gold.

This mining method requires digging into solid rock to find minerals in their raw ore form. The simplest form of lode mining is utilizing picks and shovels, but rock drills and dynamite are most often used. Shafts might go straight down into the ground or advance horizontally into a mountain faces. Shafts and tunnels are often supported with large timbers to prevent cave-ins. Deep shafts are generally accompanied by a head frame to support a hoists so material could be brought to the surface. These types of mines almost always eventually flooded as they get closer to the water table. Large pumps are used to remove the water.

This method of gold mining is responsible for recovering most of the worlds gold supply.

The startup costs for this type of mining can be extremely high. The work of drilling and basting into solid rock can be extremely dangerous and it's backbreaking labor. That is why most recreational miners concentrate on the placer gold.

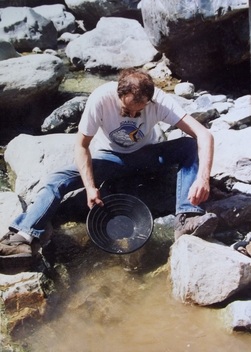

Gold Panning in a stream.

Gold Panning in a stream.

Gold Panning

This is a smaller scale of mining. Gold Panning is one of the original gold mining methods used in western mining around 1840. Panning was used when water was available. Sometimes water wasn't available so the used a method known as dry washing. Gold panning is used to wash out the light dirt and gravel. Forcing the heavy concentrates (gold, black sand and lead ) to gather in the bottom of the pan. Probably the easiest and least expensive method among all the other methods. It is the lightest to pack around and move from place to place.

Gold panning is the most basic form of mining. It really doesn't matter what your method is to remove the overburdened but when you get to the point to where you have classified the gravel down to the heavy concentrates and the precious metal, to remove the gold it always comes down to panning.

This is a smaller scale of mining. Gold Panning is one of the original gold mining methods used in western mining around 1840. Panning was used when water was available. Sometimes water wasn't available so the used a method known as dry washing. Gold panning is used to wash out the light dirt and gravel. Forcing the heavy concentrates (gold, black sand and lead ) to gather in the bottom of the pan. Probably the easiest and least expensive method among all the other methods. It is the lightest to pack around and move from place to place.

Gold panning is the most basic form of mining. It really doesn't matter what your method is to remove the overburdened but when you get to the point to where you have classified the gravel down to the heavy concentrates and the precious metal, to remove the gold it always comes down to panning.

Couple of miners dry washing

Couple of miners dry washing

Dry Washing

Dry washing is a technique used in areas with no water to recover gold. It's the preferred method in desert areas due to the dry climate. The downside however, it is very labor intensive and most of the time, it's hot in the desert. Compared to dredging or sluicing dry washing isn't very efficient. It is a lot easier to separate gold from the gravel with water because the water amplys the specific gravity of the material. Another problem with dry washing is seeing the gold, which is usually covered with dirt and it's hard to see it. Lack of water makes dry washing your only option. If the ground isn't absolutely dry the miner will have to dig up the paydirt, and lay it out on a canvas then wait for it to dry. Then the miner could run the material through the dry washer.

Dry gravel is fed on to the scalping screen of the dry washer where the finer material falls through the screen, on to the sluice section. Where it's processed over riffles. The oversized gravel falls off the back of the screen. After processing the gravel falls off the edge at the end of the sluice section. The bellows or blower is operated by hand cranking or powered by a small motor. The bellows keep everything moving.

Dry washing is a technique used in areas with no water to recover gold. It's the preferred method in desert areas due to the dry climate. The downside however, it is very labor intensive and most of the time, it's hot in the desert. Compared to dredging or sluicing dry washing isn't very efficient. It is a lot easier to separate gold from the gravel with water because the water amplys the specific gravity of the material. Another problem with dry washing is seeing the gold, which is usually covered with dirt and it's hard to see it. Lack of water makes dry washing your only option. If the ground isn't absolutely dry the miner will have to dig up the paydirt, and lay it out on a canvas then wait for it to dry. Then the miner could run the material through the dry washer.

Dry gravel is fed on to the scalping screen of the dry washer where the finer material falls through the screen, on to the sluice section. Where it's processed over riffles. The oversized gravel falls off the back of the screen. After processing the gravel falls off the edge at the end of the sluice section. The bellows or blower is operated by hand cranking or powered by a small motor. The bellows keep everything moving.

Here we have a Gold Dredge (Dredge) and a jib crane. the jib crane is used to move large rocks cant move by hand.

Here we have a Gold Dredge (Dredge) and a jib crane. the jib crane is used to move large rocks cant move by hand.

Dredging

Dredging is the most important placer-mining method today. Used worldwide is the bucket-ladder dredge, with its continuous chain of buckets rotating around a rigid adjustable frame called the ladder.

The small scale miner uses the suction dredge. Suction dredges utilize a high pressure gasoline powered water pump to suck up water, gravel and gold and inject this material into a sluice through a header box. The header box dampens the rush of water and gravel so that it flows evenly into the sluice. The sluice box then expels the worthless gravel and retains the gold.

Dredging is the most important placer-mining method today. Used worldwide is the bucket-ladder dredge, with its continuous chain of buckets rotating around a rigid adjustable frame called the ladder.

The small scale miner uses the suction dredge. Suction dredges utilize a high pressure gasoline powered water pump to suck up water, gravel and gold and inject this material into a sluice through a header box. The header box dampens the rush of water and gravel so that it flows evenly into the sluice. The sluice box then expels the worthless gravel and retains the gold.

|

|

|